Some Ideas on Aws Cwi You Need To Know

Wiki Article

Examine This Report on Aws Cwi

Table of Contents7 Easy Facts About Aws Cwi ShownSome Ideas on Aws Cwi You Should KnowThe Main Principles Of Aws Cwi Aws Cwi for DummiesGet This Report about Aws Cwi

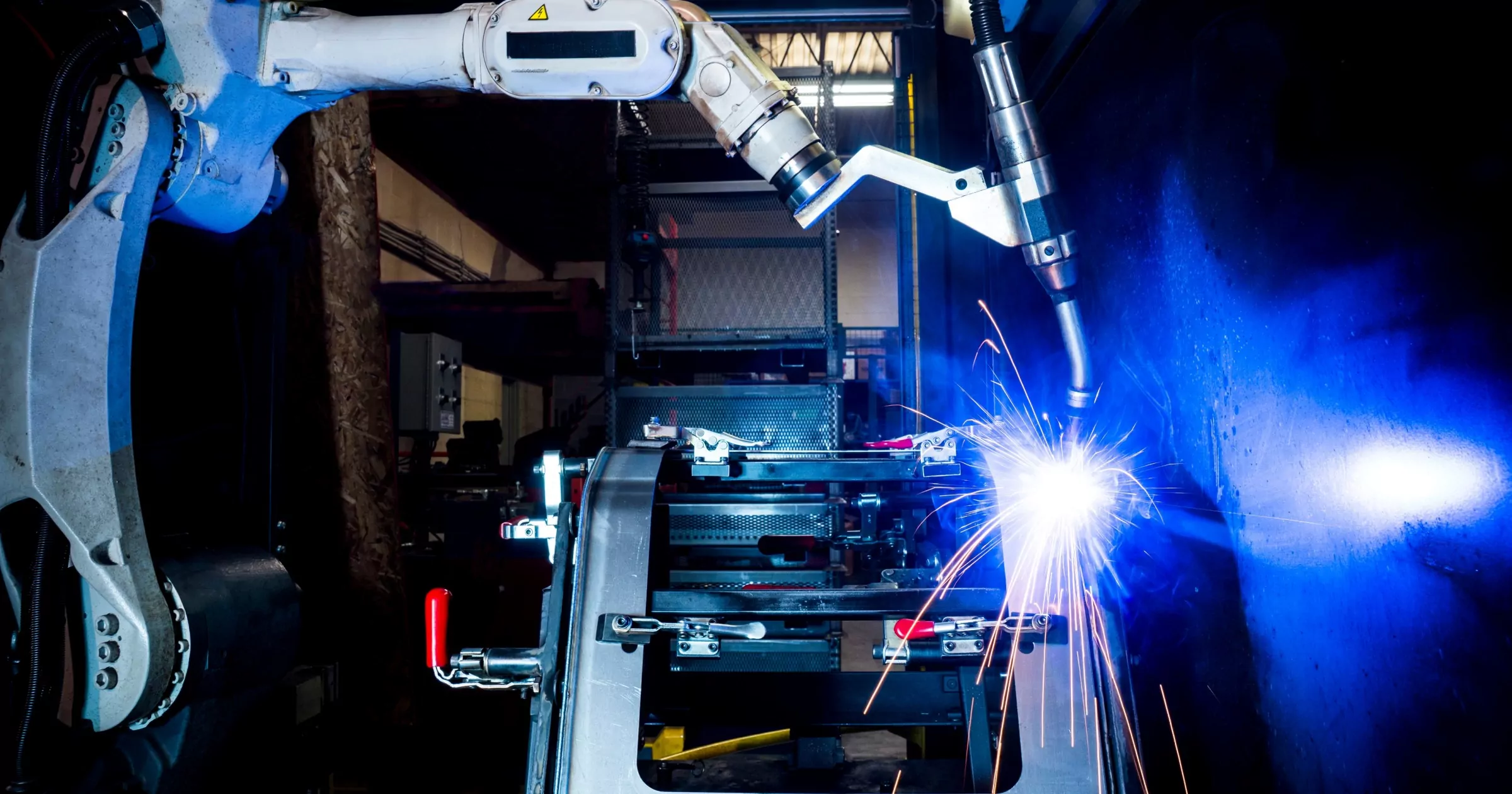

Have you ever before considered a career as a welding examiner? A welding examination certification can be valuable for a number of reasons. Maintain reading to read more and register for CWI programs with Actual Educational Solutions, Inc. today! A welding assessment accreditation is not just a terrific accomplishment, it verifies your capabilities in the welding sector.

Ending Up Being a Certified Welding Assessor shows your commitment to expanding within the welding sector. This accreditation is one that should not and will not be forgotten! As a CWI, you'll be able to capitalize on a number of various chances amongst market professionals.

Qualified Weld Inspectors are an incredibly beneficial and important property for metal fabricators. Their visibility is fairly valuable for any firm employing the makers that bring them aboard. As you might recognize, welding is just one of one of the most intricate solutions within the metal construction market. The outcome of every welding job is highly reliant upon individual welder ability.

Unknown Facts About Aws Cwi

There's no question that CWIs assistance to copyright better degrees of consistency and high quality to the welding divisions they supervise. This article supplies a brief overview of the major benefits of collaborating with a metal manufacture company that utilizes qualified weld assessors. It's not surprising that most prominent industries will certainly need you to employ certified welding assessors to manage welding.Certified welding assessors have years of experience and therefore, they recognize the nuances of conformity with welding codes. Adhering to the welding process, CWIs can carry out a series of examination to inspect the high quality of a weld, consisting of aesthetic examination, warm treatment and a hydrostatic test. AWS CWI. They can additionally make the correct adjustments to the pre-weld preparation and the in-weld treatments as needed

An in-house licensed welding examiner will certainly be able to ensure that your job is customized to all the demands of pertinent welding codes, guaranteeing its quality. Welding inspectors can evaluate welding procedure specifications, building and welding strategies, equipment calibration and welding materials. A welding inspectors ability to give welding treatment requirements uses the steel fabrication firm a substantial side of the competition, permitting producers to make welds that ideal suit specific components, instead of using tried-and-true welds.

Aws Cwi Can Be Fun For Anyone

As formerly pointed out, a CWI is not just liable fore creating the treatments for the weld, however also the quality-check testing procedures. https://www.video-bookmark.com/bookmark/6408477/aws-cwi/. Past that, welding assessors function to make sure that tools is appropriately prepped for the job which welders are able to finish their welds with skills (CWI Welding Inspector). A licensed welding inspector will certainly have had several years of experience, which a steel fabrication firm can take advantage of to ensure excellent outcomes for all manufacture projects that include welding

This is why it's critical to discover a welding firm with a skilled and extremely educated in-house licensed welding inspector on personnel. CAMM metals is such a business, so contact us today if you have a future task that requires high quality custom-made welding! It's clear that a customized steel manufacture supplier with in-house CWIs has actually devoted to spending in the top quality of its welds.

Additionally, some markets require CWIs to be associated with the production of parts. In the end, CWIs presume rather a little bit of responsibility, yet their experience shows in the last item. Below at CAMM Metals, after the welding section of the job is full, we provide many in-house solutions. These solutions include weld evaluation with color penetrant, acid cleansing and sprucing up of stainless-steel welds.

For those consumers that require licensed welds, we can certify our welds to AWS D1.1 & AWS D1.6.

9 Simple Techniques For Aws Cwi

It's crucial to note that lots of employers don't constantly require welders to be licensed. The primary distinction is that licensed welders have actually written records of their examination outcomes and their performance is frequently checked with periodic assessment( s) being component of the efficiency document for each welder.

Prior to taking the examination all PFS welders are educated, if needed, in the actual click here for more info welding procedure that they will certainly be using and they will require to have a working expertise of the welding tools, welding palatable and the material to be bonded. Effectively passing one test will certainly allow the welder to work with lots of kinds of constructions Will not enable him to function on all types of manufacture as there are certification varies imposed for each test arrangement.

Necessary variables include yet are not restricted to material type, consumable kind, material thickness and welding position. etc. After the welder has finished his examination plate or pipeline the weld is inspected utilizing the adhering to NDE procedures: Visual Assessment X-Ray Liquid Penetrant Screening Sometimes, the weld is also destructively examined.

Excitement About Aws Cwi

PFS completes this using a connection report that information all welds that a welder makes. If a welder does not use the welding process in a 6-month duration, then they shall be requalified because procedure. The benefits to using a qualification system are several however the significant advantages are: It confirms the ability of an individual to carry out in accordance with a qualified welding procedure spec (WPS) to generate an excellent weld.Report this wiki page